Down insulation is a touchy subject as more and more consumers become aware of the poor ethics some manufacturers have been accused of in recent times. Hydrophobic down is also a hot topic, offering new benefits where before it would have failed to insulate when damp.

Ben Mainwaring from Rab UK joins us to discuss the practicalities of harvesting ‘down’, new developments and the long term effects of bird flu from 2012. Plus news of the BPL outdoor show coming in Spring 2014.

Extract copied from Backpackinglight ‘Sleeping Bag Insulation’ information page

First let’s look at how insulation works.

Simply put what makes the most effective insulation is lots of small pockets of air, wrapped around us, which will trap any heat released from our body. The more pockets of air and the more ‘layers’ of those pockets, the warmer we will stay. Think fine wool fibres, big fluffy quilts, basically anything which traps lots of pockets of air which you have experienced. An ‘insulated’ jacket or sleeping bag won’t ‘get’ you warm, but it will maintain a higher level of warmth for as long as possible.

Down is lightweight and offers a greater warmth to weight ratio. However, if it gets wet or damp it becomes ineffective as the feathers can’t ‘loft’. It is possible to clean a down bag, however it is quite a long winded process to do it yourself. There are various companies offering this service thankfully for a small fee. Finally it shouldn’t be stored packed in a stuff sack. To maintain the life of the bag, it needs to be stored uncompressed.

Birds have broadly 3 types of feathers. Flight feathers (do what they say), contour feathers (these are the ones that are like flight feathers on the top but towards the base become more fluffy)and down feathers. These are the best to use as they are tiny, soft and poorly developed. They grow continuously on the bird even after being harvested.

Down is an excellent thermal insulator due to its ability to trap lots of small pockets of air. It is these small pockets which insulate us so effectively. This is why it is used for sleeping bags combining insulation with minimal weight and compressible bulk. Down bags tends to be more expensive than synthetic because it is a natural product that needs to be collected using manual labour, not manufactured with a machine. As with anything, the quality of down can vary depending on several different factors.

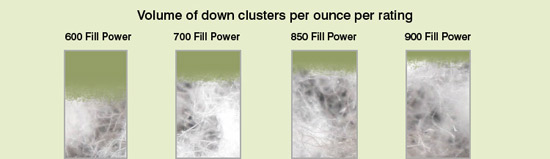

Down is rated using the term ‘Fill Power’. The higher the Fill Power rating ie 850, the better the down and finer the feathers sourced from a quality supply. The lower the number ie 650 the lower the grade of the down and supply source, but cheaper too.

The best down comes from duck or geese who live in colder climates such as Siberia, Eastern Europe, Canada or the Pyrenees. It is sourced from older birds that have had balanced nutrition. Finally quality down has to have been prepared, transported and graded correctly. Eg the birds need to be plucked in the spring when the down is strongest, cleanest and the natural time for birds to moult.

Harvesting the down can be mechanical when the birds are dead, by hand when the birds are dead or by hand when the birds are alive. The latter is now considered unethical and generally not used by quality sleeping bag producers, who now comply to new Code of Conduct and a Traceability Standard which European Down and Feathers Association (EDFA) members are required to follow.

The more down you have in a sleeping bag the warmer it will be. However, you also need to consider the Fill Power of a bag. This refers to the quality of the down you are putting in. The higher the number the better the quality. 800FP or more is very good. So for example the Rab Neutrino 400 weighs 805g and has a fill of 400g of down which is 800FP European Goose Down.

If other feathers are added to the fill, the insulation properties drop and so does the price! The best ratio is 95/5 which means that for every 100g of material used 95 grams will be down and the other 5 will be made up of feathers. Due to the nature of ‘sorting down’ it is almost impossible to have 100% down as trying to separate all the feathers from the down is a difficult process!

To add confusion to this traditional history you need to be aware that Hydrophobic down is just about to emerge on the market. As we understand it Rab are using Nikwax technology on the down prior to it being used in the bags. It will have the benefits of absorbing less water, dry faster, retain loft better and will be fluorocarbon free. We are awaiting confirmation the insulation properties will be unaffected.